Manufacturing Capabilities

Sheet Metal Industry

CNC Laser Cutting

CNC Punching

CNC Bending

Fabrication

Pretreatment

Assembly

Other Machineries

CNC Laser Cutting

CNC Laser Cutting

- Total Number Of Machines: 3

- TruLaser 1030, Trumpf [3 kW]

- BAISHENG Laser [1.5 kW]

- SMART Laser [1 kW]

- Cut all types of sheet metal, aluminium and brass sheets quickly and to a high standard

- Capacity : MS - upto 25mm; SS - upto 20mm; Al - upto 4mm

- Intricate contours can be cut precisely and burr-free.

- Excellent edge finishing that eliminates the need for deburring and polishing

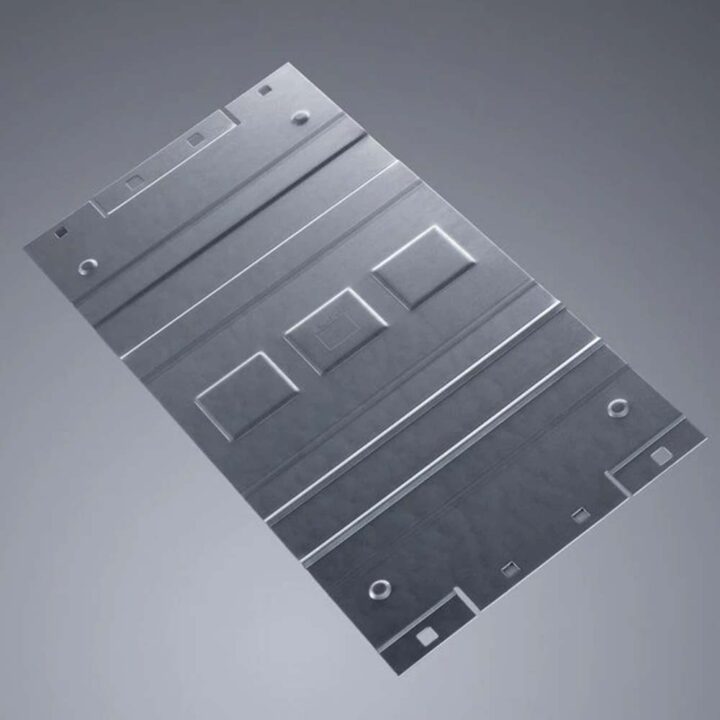

CNC Punching

CNC Punching

- Total Number Of Machines: 2

- TruPunch 2000, Trumpf

- TruPunch 2020, Trumpf

- Punching Capacity [SS - 0.6mm to 2mm ; MS - 0.6mm to 6mm].

- Quick & Precise while also preventing the creation of waste.

- Can produce geometrically exact and high-quality shapes.

CNC Bending

CNC Bending

- Total Number Of Machines: 11

- Hindustan Hydraulic CNC Bending Machine [110 T, Qty 1]

- Harsle CNC Press Brake Machine [30T, Qty 6 ; 120T, Qty 1 ; 160T, Qty 1]

- Yawei CNC Bending Machine [110 T, Qty 1]

- YSD CNC Bending Machine [40T, Qty 1]

- Bending capacity of 3m X 6mm mild steel and 3m X 2mm stainless steel.

Fabrication

Fabrication

- Total number of machines:

- XT Handheld Automatic Laser Welding Machine (Qty 1)

- MIG/TIG/Arc Welding Machine (Qty 28)

- Spot Welding (Qty 6)

Pretreatment

Pretreatment & Powder Coating

- 11 tank conveyorized pre-treatment and powder coating plant.

- Both batch and conveyor system

- Drier towards the end to ensure that the components are fully prepared for powder coating.

- Total 2 conveyor type system and 1 batch type oven

- Dry Film Thickness(DFT) Coat thickness range 0-2000 microns. Last count 0.1-1 microns.

Assembly

Assembly & Packing

- Designated area for final product assembly and packaging: 12000 Sq. Ft. Area overall

- Products are well wrapped to prevent damages , dirt and dust.

- For modular furniture, final assemblies are carried out on site for Marine products.

Other Machineries

Other Machineries

- Power Press Machine:

- (Qty 10, ranging from 107 to 2007)

- Power: Electrical

- Material: Mild Steel

- 3 Axis Pipe Bending Machine: Qty 1

- Pipe Cutting Machine : Qty 2

- Forklift : Qty 1

Wood Industry

Wood Machining Centre

Panel Saw

EDGE BANDING MACHINE

BORING MACHINE

COLD PRESS MACHINE

Wood Machining Centre

Wood Machining Centre

- CNC ROUTER CENTATEQ P-100 ; HOMAG

- 2 CNC Controlled Z axes

- 2 field / 4 field operation

- Software optimized of the working field

- 12 HP (9 kW) HSK routing spindle

- High processing speed

Panel Saw

Panel Saw

- SLIDING TABLE PANEL SAW K32 ; HOMAG

- Machine uses high precision spindles

- Main Saw Speed 3000RPM; Saw Power 5.5kW

- Quick speed change mechanism (3000, 4000, 5000)

- Dust collection ducts to minimize dust waste

EDGE BANDING MACHINE

Edge Banding Machine

- UNIVERSAL EDGE BANDING MACHINE EDGETEQ T-200 ; HOMAG

- SINGLE SIDED EDGE BANDING MACHINE EDGETEQ S-230 ; HOMAG

BORING MACHINE

Boring Machine

- J-2102.in Double head Multi boring (Semi Auto) ; Jai Industries

- EASY AND QUICK PRECISION BORING

COLD PRESS MACHINE

Cold Press Machine

- MODULAJ2102.IN HYDRAULIC COLD PRESS 50TON ; Jai Industries

- Heavy duty platen designed to take maximum compression loads.

- Pressing platen is synchronized on rack & pinion for smooth up-down movement with eccentric rollers.